Driven by innovation.

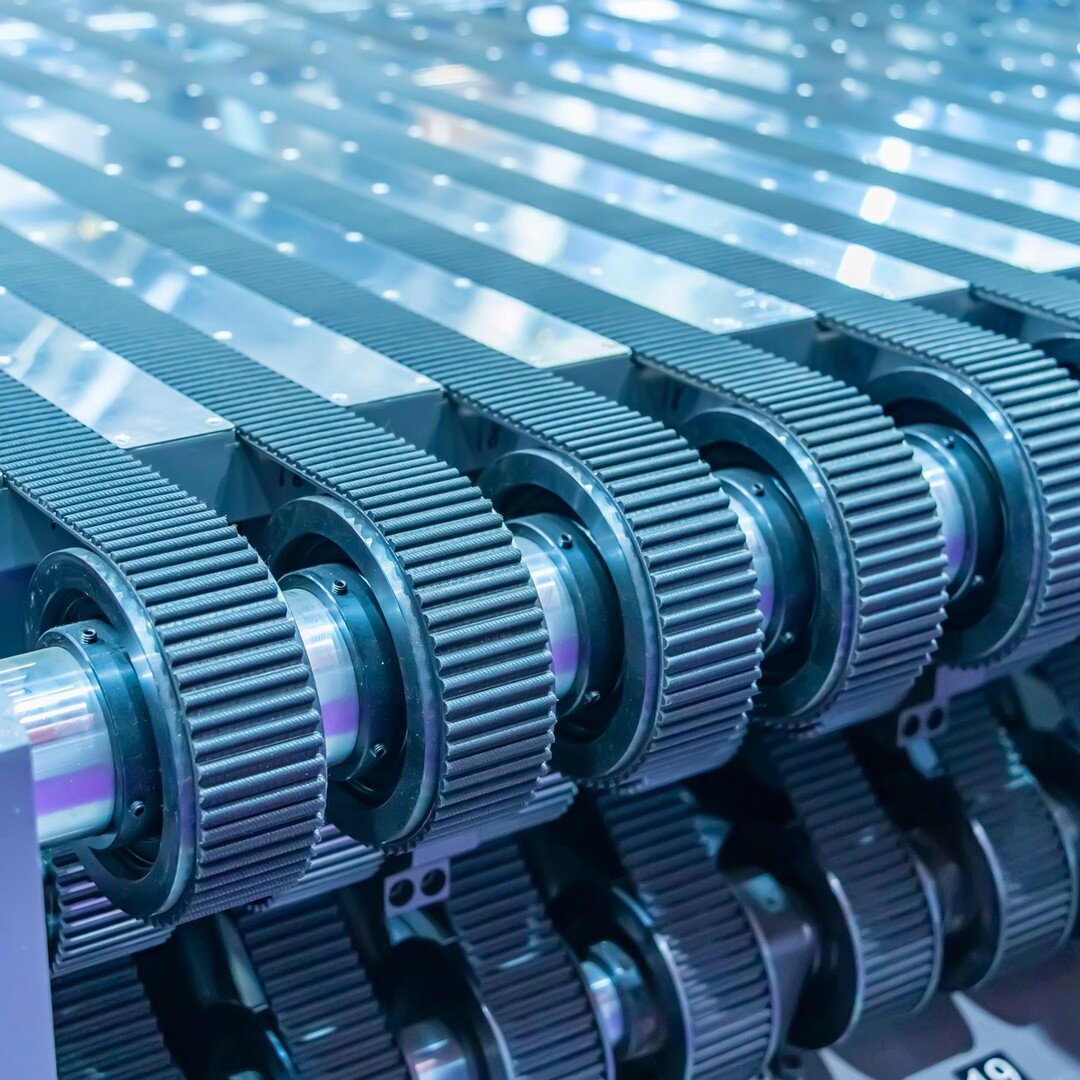

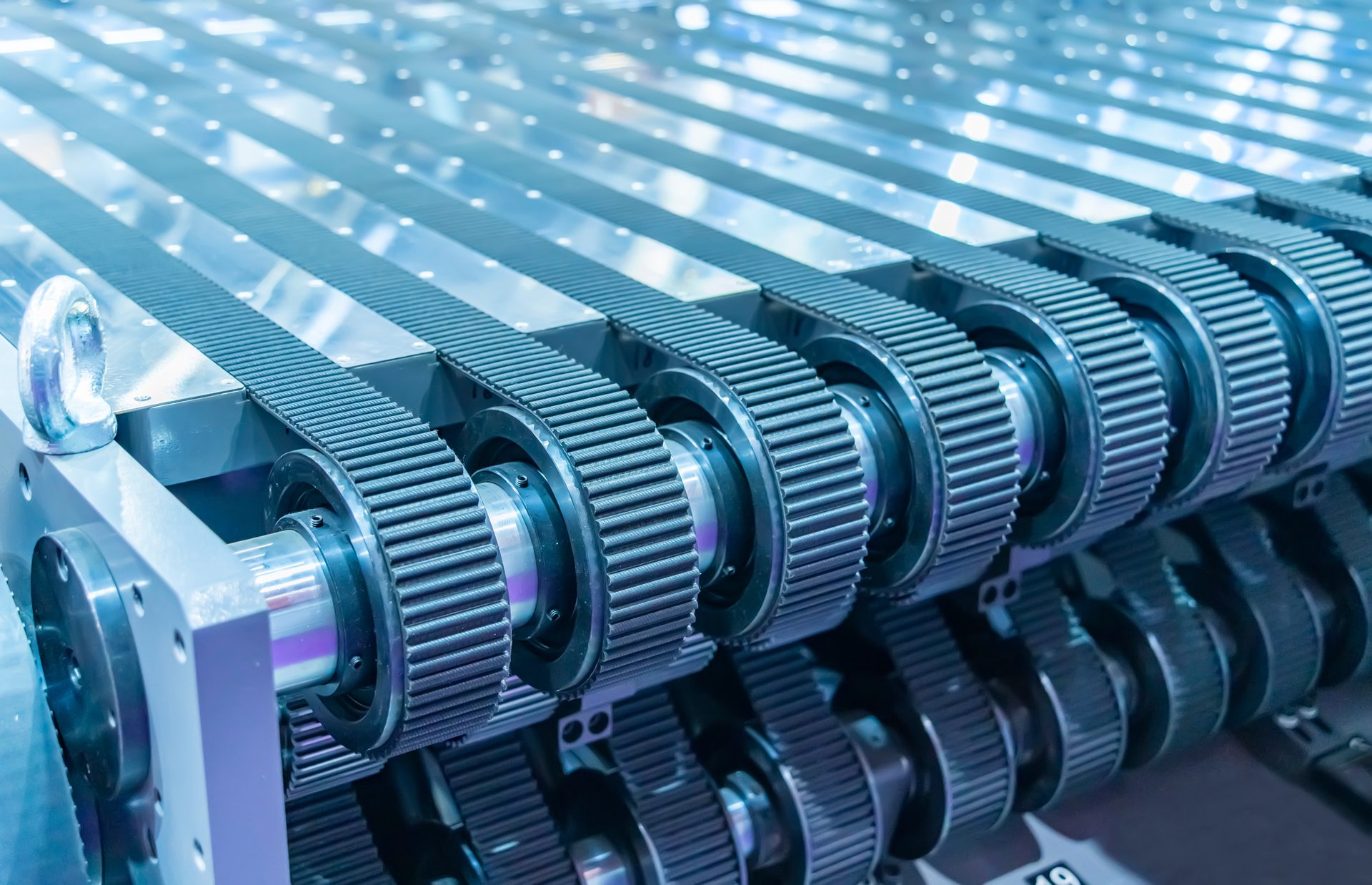

Polyurethane belts engineered for performance.

Length, width, depth, pattern, and substrate, color — so much goes into creating the perfect polyurethane performance timing belt.

Whether you require a standard timing belt or your application requires something special, Chemi-Flex provides whatever your needs require. Because we have everything you need under one roof, we can custom-configure the best possible solution to fit your needs. Design, concept, chemical engineering, execution, testing, and end-to-end problem-solving all come to bear on the perfect solution at the best price possible.

Our Capabilities

Chemi-Flex serves as a reliable source for both high-volume OEMs and low-volume customers offering a diverse range of molds for producing timing belts in English and metric pitch. We specialize in designing and fabricating molds on-site for various applications, as well as utilizing existing tooling to produce custom profiles and standard products — all in our modern state-of-the-art facility. We are committed to providing engineering services and laboratory resources for developing application solutions, upgrading manufacturing techniques, and researching new raw materials. Our modern laboratory is fully staffed with dedicated Chemical and Mechanical Engineers, equipped with up-to-date testing equipment for extensive Research and Development and Quality Assurance.

Design & Engineering

With a full staff of mechanical, chemical, and process engineers, Chemi-Flex offers comprehensive engineering assistance throughout the customer design phase. Examples of some of the many services we offer our clients include first article inspection and testing, custom test fixtures, 3D CAD belt and mold design, a fully equipped machine shop, an extensive database of materials and costs, and in-depth chemical analysis of raw materials and finished goods.

Molds & Tooling

Timing belts are not always an off-the-shelf solution. Whatever the need Chemi-Flex offers a full range of standard molds in both metric and English pitches. If you are searching for a custom solution, we can provide that as well. We are capable of walking through the entire process with our customers in order to develop any specialized molds that are needed to fulfill their manufacturing needs. It’s important to know that no matter the need, we can provide whatever is necessary to get the job done, and all under one roof.

Manufacturing

Chemi-Flex takes pride in manufacturing quality parts designed to meet or exceed the demands of our customers. Before releasing new designs for production, each step of the manufacturing process is measured and quantified during a supervised pilot run, which is conducted by our engineering and quality departments. Following our initial molding process, we offer a variety of finishing services to help meet the needs of our customers. Our secondary manufacturing services include slitting, surface grinding, splitting, hole punching, stamping, and washing.

Design

Assistance

If you're looking for a qualified set of helping hands in the design solution for your manufacturing process, just reach out and let us know if you would like to start a conversation. We can guide you through the entire process or just plug ourselves in where you need us to be the expert. We’re happy to do it and love this side of the developmental process. Give us a little basic information and we will get right back to you.

Process solutions are only as good as their weakest link. We work to replace any weak links with industry experts so the process is productive, exacting, and affordable.

Why Chemi-Flex: Most of the time, it's the need for full-service solutions that drives people to Chemi-Flex.

We have a history of being one of only a few organizations that offer full end-to-end solutions all under one roof. That is a convenience that is exacting and helps to reduce cost in proof of concept.

Key Stats: Supporting Why Chemi-flex.

50

Years In Business - Since 1971

10k

Over 10,000 SKUs

35+

Countries Served

Our Products

Chemi-Flex specializes in offering a variety of standard and unique product solutions, including open-ended and truly endless belts with a variety of tooth forms and backside profiles to suit any need. We currently have over 10,000 formulations available, which helps to ensure that we can provide any client with an ideal fit for any application, no matter the parameters.

Industries we serve

-

This is a highly regulated vertical that requires a truly unique supply partner that is able to concept, design, execute, and provide documented testing necessary that will fulfill exacting requirements for polyurethane belts to manufacturing equipment that is engineered with finite medical tolerances in mind. Many OEMs trust our timing belts in their equipment so that hospitals and diagnostic facilities can provide continual vital care to their patients.

-

The intricacies of this consumer vertical are driven by extended life requirements and certain rigidity requirements for product applications that have hundreds and thousands of differentiators. These specifics range from Thermo requirements to elasticity and durability which all impact the substrate and overall composite spec necessary to achieve success.

-

Timing belts, fan belts, servo-drive belts, and many others make up this vertical’s needs. An automotive timing belt is an essential component of an internal combustion engine that synchronizes the rotation of the crankshaft and the camshaft. Timing belts are typically made from high-quality materials such as rubber or reinforced synthetic materials to endure the rigors of high speeds and extreme temperatures.

-

Literally all shapes and sizes, anything from huge industrial mechanisms to micro tech that can fit in the palm of your hand, they all transfer energy for movement by using belts of various lengths, widths, composite, and tooth configurations. When it comes to machinery, the timing or delivery belt is an integral part of the production and executional process that dictates energy transfer from one environment to another.

-

If it comes in contact with food or beverages meant for human consumption, it has to be and stay sanitary. Whether it's drive, sort, or transport applications, you need proven, expertly engineered components. Quite often, specialty materials and coatings are required, and together, we can develop individual belts and conveying elements for any application. Take advantage of our technical expertise and innovation to optimize existing production processes and exceed previous performance limits.

-

As a subset of the medical vertical, this branch has high hygienic standards as well, production requirements are subject to increased requirements for cleanliness and purity. That means that only selected materials that have been approved for this purpose may be used for transport and conveying tasks. The belts manufactured for these applications must be resistant to corrosion, abrasion, and acids and easy to clean.

Stay connected.

Follow us @chemiflex